FREQUENTLY ASKED QUESTIONS

If you have any queries about IBC Wiring Harness Solutions, give us a call.

In the meantime, read through the list of frequently asked questions we've put together for your convenience.

What is a wiring harness?

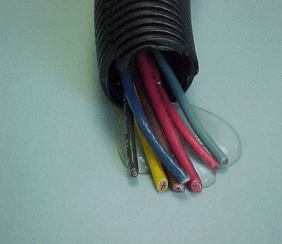

A wiring harness is the organisation of a set of wires and connectors. The harness binds the wiring together, often by nylon or copper braiding, moulded plastic, rubber or vinyl. The harness allows for the smooth transmission of power and electrical signals through a piece of equipment or vehicle.

Why should we use braid over tubing?

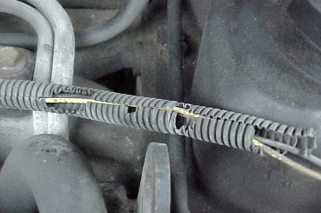

Wire harnesses protected by braided technology, are designed to last longer than harnesses covered with convoluted tubing, which are designed for a maximum load of 70-80% wire, leaving the rest of the tubing to be free air space. This allows wires to move around with equipment vibration, reducing the insulation layer of the wires, where the conductor can become exposed and cause electrical failure. Braided technology considerably reduces the wire to wire movement by having 100% loading of the wires which ensures there is less insulation wear and deterioration. Braided wire harness assemblies are tightly bound, consequently preventing abrasive material entering and causing damage to the insulation on the wires. Whereas convoluted tubing with the free space, allows for dirt and particulates to accumulate through the open ends, adding to the erosion and deterioration of the wire insulation. The braided wire harness assembly has a small opening, which allows air and fluids to pass through, resulting in no harm to the insulated wires. Due to the breathable qualities of the braided wire harness assembly, there is an improved heat resistance ensuring a longer lifespan. Due to the nature of the Braided wire harness, the assemblies will have a longer lifespan when compared to those made with convoluted tubing, which last approximately 1-3 years, where the harnesses protected with braided wire harness technology last 9-11 years.

Using tubing will result in vibrations of cables in plastic, tubing will become a water trap.

Why would I need a custom wiring harness?

A custom wiring harness can save you time and money for a number of reasons:

• They offer protection to cables

• Cut installation costs

• Improve quality of installations

• Reduce risks of electric shorts

• Improve performance of equipment

I don't have plans or schematics. Can you make me a replacement wiring harness?

Yes, we can. If you supply us with a functioning unit we can reverse-engineer a wiring harness.

Do you braid your harnesses or outsource the work?

We design, build and braid all our harnesses at our Mackay workshop using quality materials and expert workmanship.

About Us

IBC Wiring Harness Solutions specialises in wiring harness design and production for mining, automotive and aviation applications. Based in Mackay, our expert technicians will custom-design assemblies to your exact specifications. Contact us today to discuss your requirements and get a quote.

Company Information

Address:

Mackay QLD

Phone:

0427 067 257

Operating Hours:

Monday-Sunday

7:00 AM - 5:00 PM